Pathways to a Green Ammonia Future: Exploring Sustainable Production Technologies

- Boreum Lee, Ph.D.

- Green NH₃ , Research Summary

- May 19, 2025

Introduction

Ammonia (NH₃) is among the most crucial industrial chemicals in the world today, with approximately 85% of global production directed toward agricultural fertilizers that sustain our growing population. Beyond its traditional role in agriculture, ammonia is increasingly being recognized as a promising carbon-free hydrogen carrier for energy storage and transportation systems of the future.

In our recent research paper, “Pathways to a Green Ammonia Future,” published in ACS Energy Letters, we present a comprehensive technoeconomic analysis and environmental assessment for large-scale green ammonia production using different water electrolysis technologies powered by renewable energy. This study aims to identify the most economically and environmentally viable pathways to decarbonize ammonia synthesis and contribute to a sustainable future.

Why Green Ammonia Matters

The conventional Haber-Bosch ammonia synthesis process paired with steam methane reforming (SMR) for hydrogen production consumes a staggering 1-2% of global annual energy and generates approximately 235 million tons of CO₂ emissions yearly. Approximately 80% of these emissions come from hydrogen production via SMR.

In our recent paper published in ACS Energy Letters, my colleagues and I evaluated pathways to decarbonize ammonia production through a comprehensive technoeconomic and environmental assessment. We compared various water electrolysis technologies that could replace the carbon-intensive SMR process when powered by renewable energy sources.

Comparing Water Electrolysis Technologies

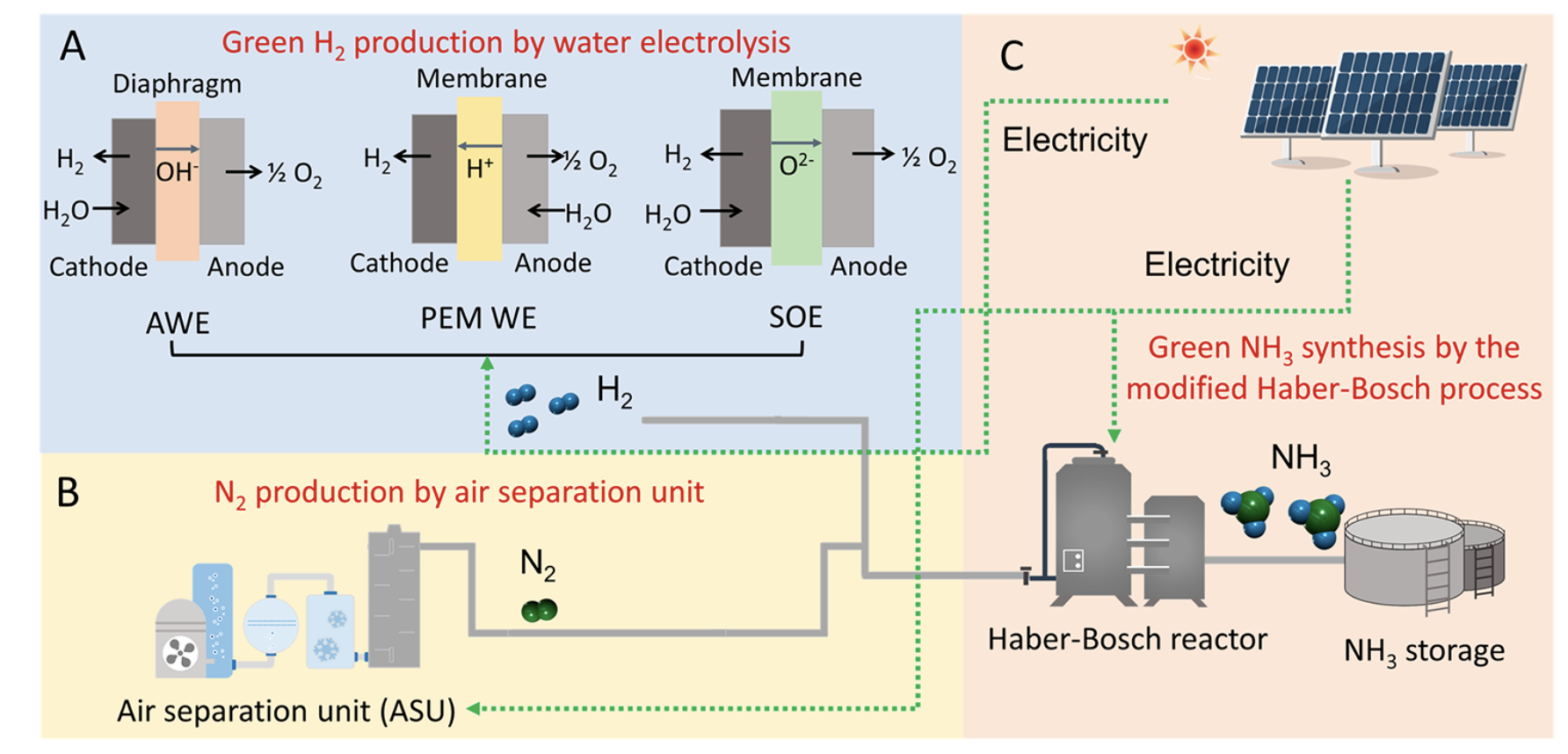

Our research examines three major water electrolysis technologies that could revolutionize ammonia production:

Alkaline Water Electrolysis (AWE) - The most mature technology with a high technology readiness level (TRL) and lower capital expenditure due to less expensive catalysts

Polymer Electrolyte Membrane Water Electrolysis (PEM WE) - Offers advantages of solid polymer electrolyte, high compactness, flexible operation, and high-pressure capabilities

Solid Oxide Water Electrolysis (SOE) - Shows promise for large-scale green hydrogen production with high system efficiency due to favorable thermodynamics at high operating temperatures

We conducted scenario-based economic projections and environmental impact assessments for each technology, evaluating how they might perform through 2050 under different conditions.

Key Findings

Our analysis shows that green hydrogen production can become economically competitive with conventional hydrogen from steam methane reforming under certain conditions. For the best-case scenario, hydrogen prices are projected to become less than 2.16 USD/kg for AWE and SOE in 2035 and 2036, respectively.

While AWE currently offers the lowest hydrogen cost (AWE < PEM WE < SOE), our projections indicate that by 2050, SOE might become the most economically favorable option (SOE < AWE < PEM WE). This shift would occur because SOE has both higher system efficiency and learning rate potential compared to other technologies.

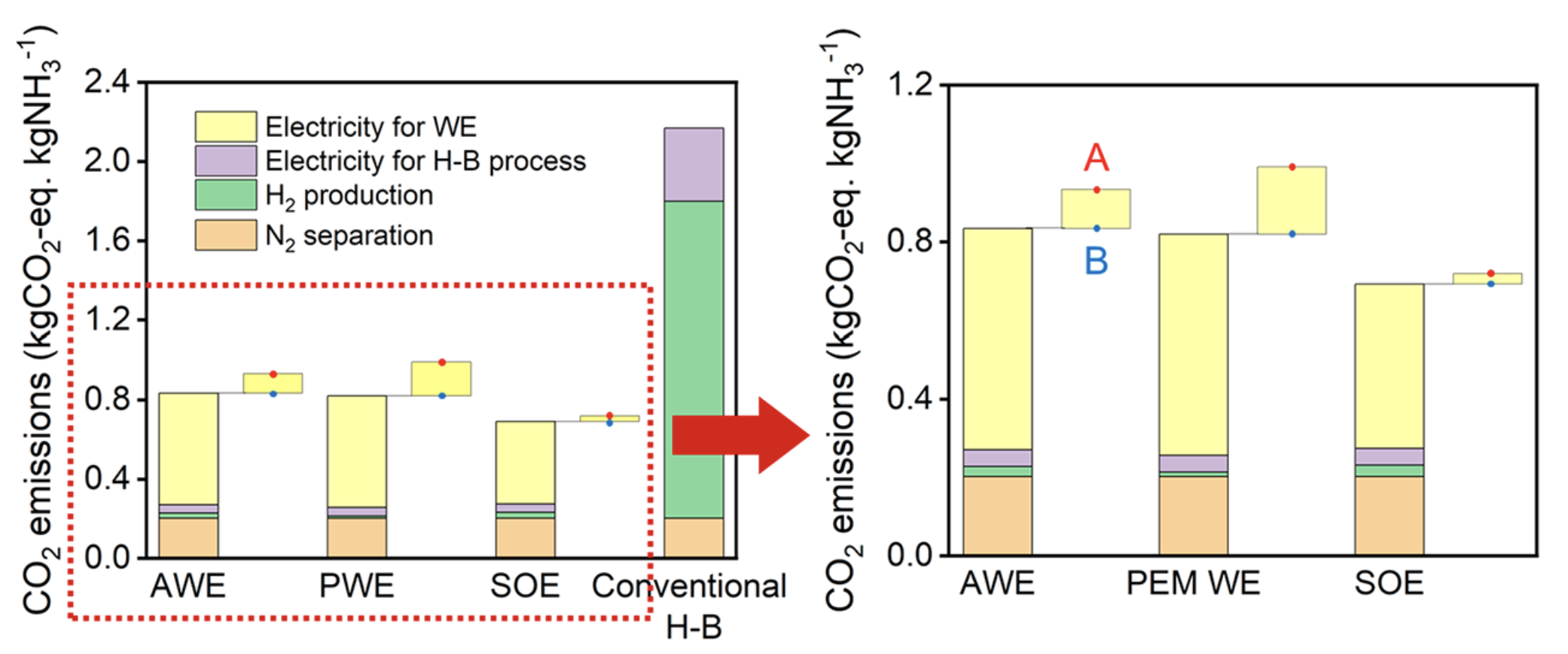

From an environmental perspective, green ammonia production using any of the three electrolysis technologies demonstrates significantly lower CO₂ emissions than the conventional Haber-Bosch process. SOE offers the lowest emissions, followed by AWE and PEM WE.

Carbon Pricing Impact

One particularly interesting finding from our research is how carbon pricing policies could accelerate the economic competitiveness of green ammonia. With a CO₂ tax in place, green ammonia synthesis using any of the three electrolysis technologies could become competitive with conventional Haber-Bosch ammonia production more than a decade earlier than without such policies.

Looking Forward

The transition to green ammonia production represents a critical opportunity to significantly reduce industrial carbon emissions while maintaining essential fertilizer production and developing new carbon-free energy vectors. With improvements in electrolyzer energy efficiency, decreases in water electrolyzer capital costs, and reductions in renewable electricity costs, green ammonia has the potential to reach economic parity with conventional ammonia production.

Our integrated technoeconomic and environmental analysis provides a quantitative roadmap for researchers, industry leaders, and policymakers to guide environmental policies and the ammonia economy toward widespread implementation of green ammonia production.

If you’re interested in learning more about our research, you can find the full paper, “Pathways to a Green Ammonia Future,” in ACS Energy Letters (2022): https://doi.org/10.1021/acsenergylett.2c01615

Tags :

Share :

Related Posts

Getting Started with LCA and SimaPro

Introduction to Life Cycle Assessment I studied Life Cycle Assessment through the “Life Cycle Assessment Student Handbook” (2015). The first section, which provides an overview of Life Cycle Assessment, highlights two key requirements for performing an Life Cycle Assessment:

Read More

Free Usage Method and Tutorial for SimaPro for Life Cycle Assessment

Introduction to Accessing and Using SimaPro This article explains the process of utilizing existing inventory databases in SimaPro to calculate carbon dioxide emissions. I am using SimaPro version 9.1.0.11. Before making the investment in purchasing a full license, you can evaluate the software by using a demo version available for approximately 30 days.

Read More